Printed Parts | Resin Supply | Custom Material Development

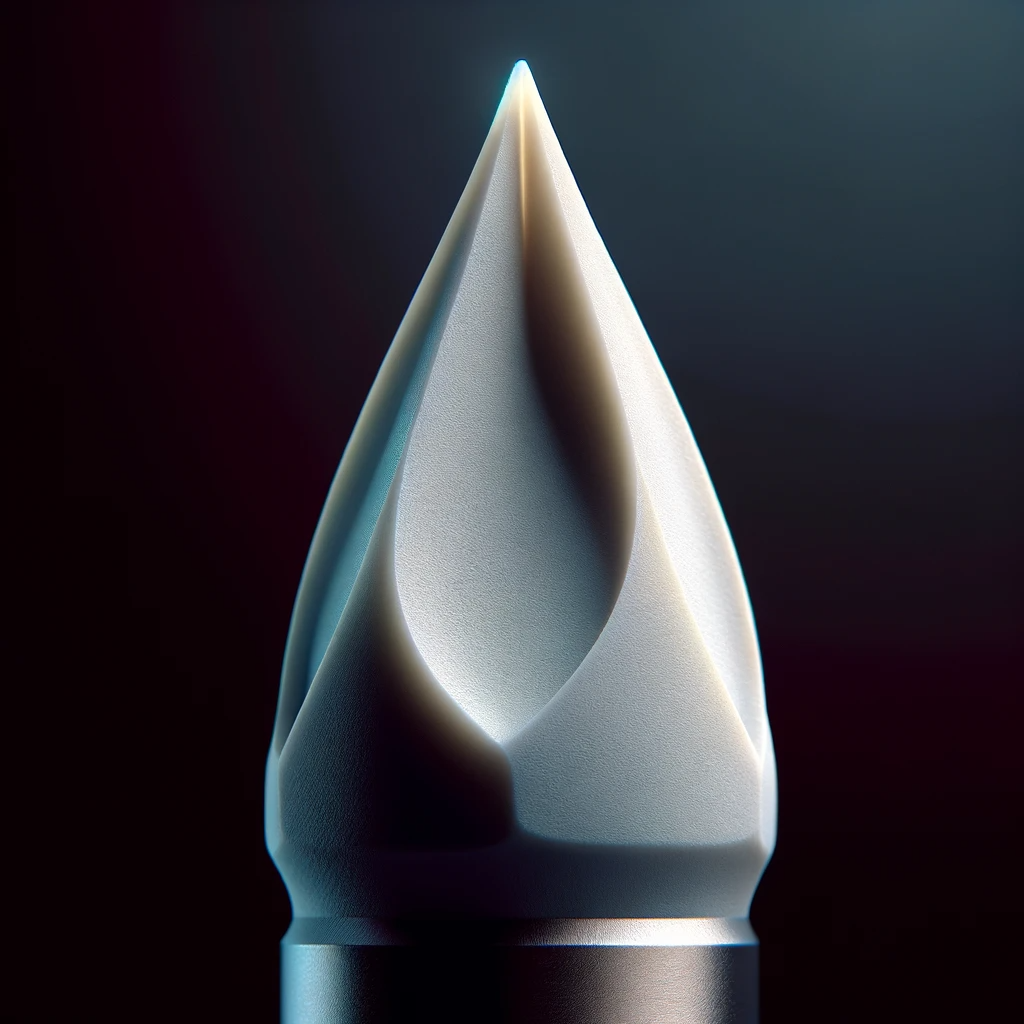

Ceramic 3D printing is ideal for rapid prototyping, quick design iterations, and low-to-medium volume production. The design freedom that 3D printing allows can truly be an enabling technology, especially considering the fact that added complexity and features often come without added cost. With nearly 30 years' experience, SINTX is an industry leader in ceramic 3D printing and works with a wide range of partners from innovative startups to well-established OEMs. Our expertise spans a variety of technical ceramics including silica, zirconia, alumina, and silicon nitride, as well as our proprietary silicon nitride composite filament, Flex-SN PEEK.

Connect with our team of engineers to explore how our ceramic 3D printing services can transform your product development process, maximize efficiency, reduce costs, and accelerate time-to-market for high quality, 3D printed ceramic parts.